OEM manufacturer Dorking Feed Additive - Melt-blown fabric substitute – Nanofiber membrane composite material – E.Fine

OEM manufacturer Dorking Feed Additive - Melt-blown fabric substitute – Nanofiber membrane composite material – E.Fine Detail:

Melt-blown fabric substitute - Nanofiber membrane composite material

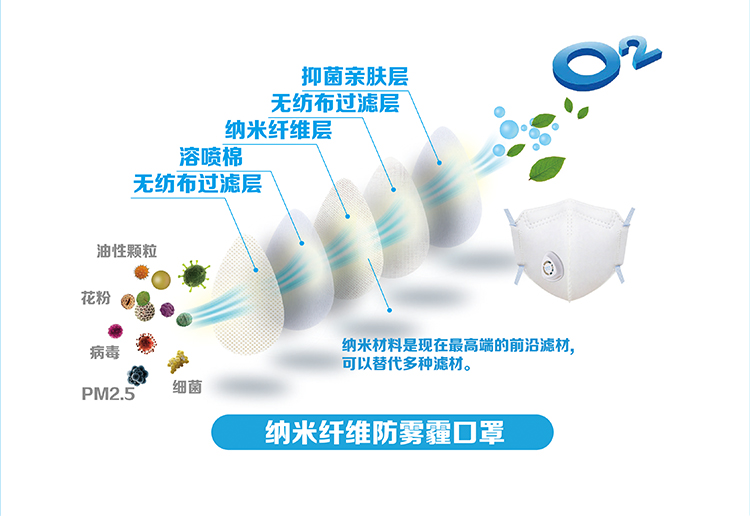

Electrostatically spun functional nanofiber membrane has small diameters, about 100-300 nm, It has the characteristics of light weight, large surface area, small aperture and good air permeability etc. Let’s realized precision filters in air and water filter special protection, medical protective material, precision instrument aseptic operation workshop etc., Current filter materials can’t compare with it as the small aperture.

Melt-blown fabric is widely used on the current market, It is PP fiber through high-temperature melting, the diameter is about 1~5μm.

The Nanofiber membrance made by Shandong Blue future , the diameter is 100~300nm

In order to get better filtering effect for the melt-blown fabric in current marketing adopt electrostatic adsorption. the material is polarized by electrostatic electret, with a stable charge. To achieve high filtration efficiency, low filtration resistance characteristics. But the electrostatic effect and filtration efficiency will be affected seriously by ambient temperature humidity. The charge will attenuate and disappear with time. The disappearance of the charge causes the particles adsorbed by the melt-blown fabric to pass through the melt-blown fabric. The protection performance is not stable and the time is short.

Shandong Blue future’s nanofiber is physical isolation, Do not have any effect from charge and environmental. Isolate contaminants on the surface of the membrane. The protection performance is stable and the time is longer.

Because the melt-blown cloth is a high temperature processing technology, it is difficult to add other functions to melt-blown cloth, and impossible to add antimicrobial properties through post-processing. As the electrostatic properties of the melt-blown fabric are greatly reduced during the loading of the antimicrobial agents, Let it has no adsorption function.

The anti-bacterial and anti-inflammatory function of filtering material on market, the function is added on other carriers. These carriers have large aperture, bacteria are killed by impact, the missing pollutant attached to the melt-blown fabric by static charge. Bacteria continue to survive after the static charge disappeared, through the melt-blown fabric, the antibacterial function is greatly reduced, and leakage rate of pollutants is high.

Nanofiber membrane instead of the melt-blown fabric , Lasting protection ; filtration and protection are more efficient. it will be new direction of protection .

Product detail pictures:

Related Product Guide:

US insect in-feed use to expand to new species, ingredients Menu Back to Back to Back to Back to Back to Back to Back to Back to Send Follow us on Facebook Follow us on Twitter Follow us on LinkedIn Send contact Email to a friend Facebook Twitter Linkedin | Livestock Betaine

Push on to make US poultry sector sustainable with feed Menu Back to Back to Back to Back to Back to Back to Back to Back to Send Follow us on Facebook Follow us on Twitter Follow us on LinkedIn Send contact Email to a friend Facebook Twitter Linkedin Ti | Probiotics For Aquaculture

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for OEM manufacturer Dorking Feed Additive - Melt-blown fabric substitute – Nanofiber membrane composite material – E.Fine , The product will supply to all over the world, such as: Kuala Lumpur, Ethiopia, Durban, We pay high attention to customer service, and cherish every customer. We've maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!